Home / Conduit construction / District heating

District heating

District heating pipelines

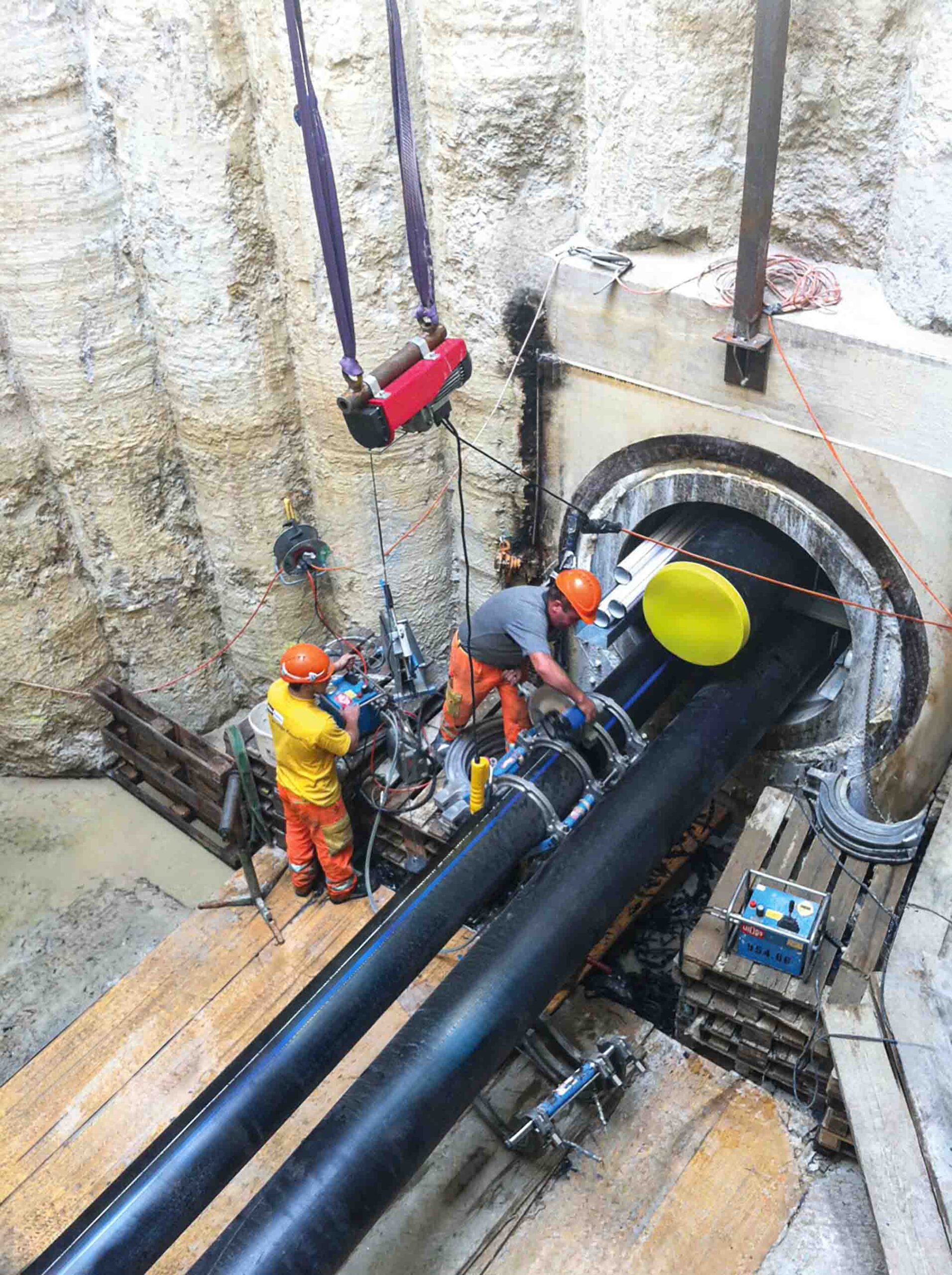

District heating is a sustainable and efficient heat supply solution that is particularly suitable for residential areas, commercial buildings and industrial plants. It uses centrally generated heat, which is transported to the consumers via a well-designed pipeline network. Our range of services includes the planning, construction and maintenance of district heating pipelines. In doing so, we rely on modern materials. We lay district heating pipes with plastic casing pipes as well as polyethylene cooling and anergy pipes. We also construct extensions and

house connections to existing networks and carry out the post-insulation of plastic casing pipes with suitable specialist personnel. Depending on the project requirements, we lay the pipes underground, in microtunnels or shafts. We manufacture special components and fittings ourselves in order to

to ensure maximum accuracy of fit. We are always available to you flexibly and reliably for repairs and maintenance of existing lines.

Through precise planning, innovative technology and a manufacturer-independent selection of materials, we create tailor-made solutions for a reliable and sustainable heat supply - flexible, economical and future-proof.

Energy center / plant construction

In the field of energy centers and plant construction, we offer tailor-made solutions for heat supply. We install heat transfer stations with heat exchangers, fittings, pumps and pipelines and take care of the expansion and extension of existing systems. Our focus is on efficiency, durability and the highest quality to ensure a reliable and sustainable heat supply.

Plastic piping

The diversity of our product range allows for customized solutions for a wide variety of applications in water and gas supply. Our products can be used to connect pipes, fittings, valves and other components safely and reliably, whether for main pipes, house connections or hydrants. Safety always comes first - especially when the elements to be connected are made of different materials.

Plastic pipes are suitable for numerous different areas of application thanks to the diverse properties of the plastics used. Their low weight, high strength and flexibility are particularly advantageous. In addition, plastic pipes are not only cost-efficient and offer a long service life, they are also resistant to many everyday chemical substances such as acids, alkalis, salts and oxidizing agents.

Welded pipe systems made of polyethylene

Pipes and pipe components made of polyethylene can be joined together thermally or mechanically. The most important thermal processes are heating element butt welding and electrofusion welding. Welded pipe systems are absolutely leak-proof and do not require any additional sealing elements. Push-fit and clamp connection techniques are mechanical connections that are mainly used for house connections.